Manufacturing just got easier with "Fox ERP for Manufacturing."

FoxERP

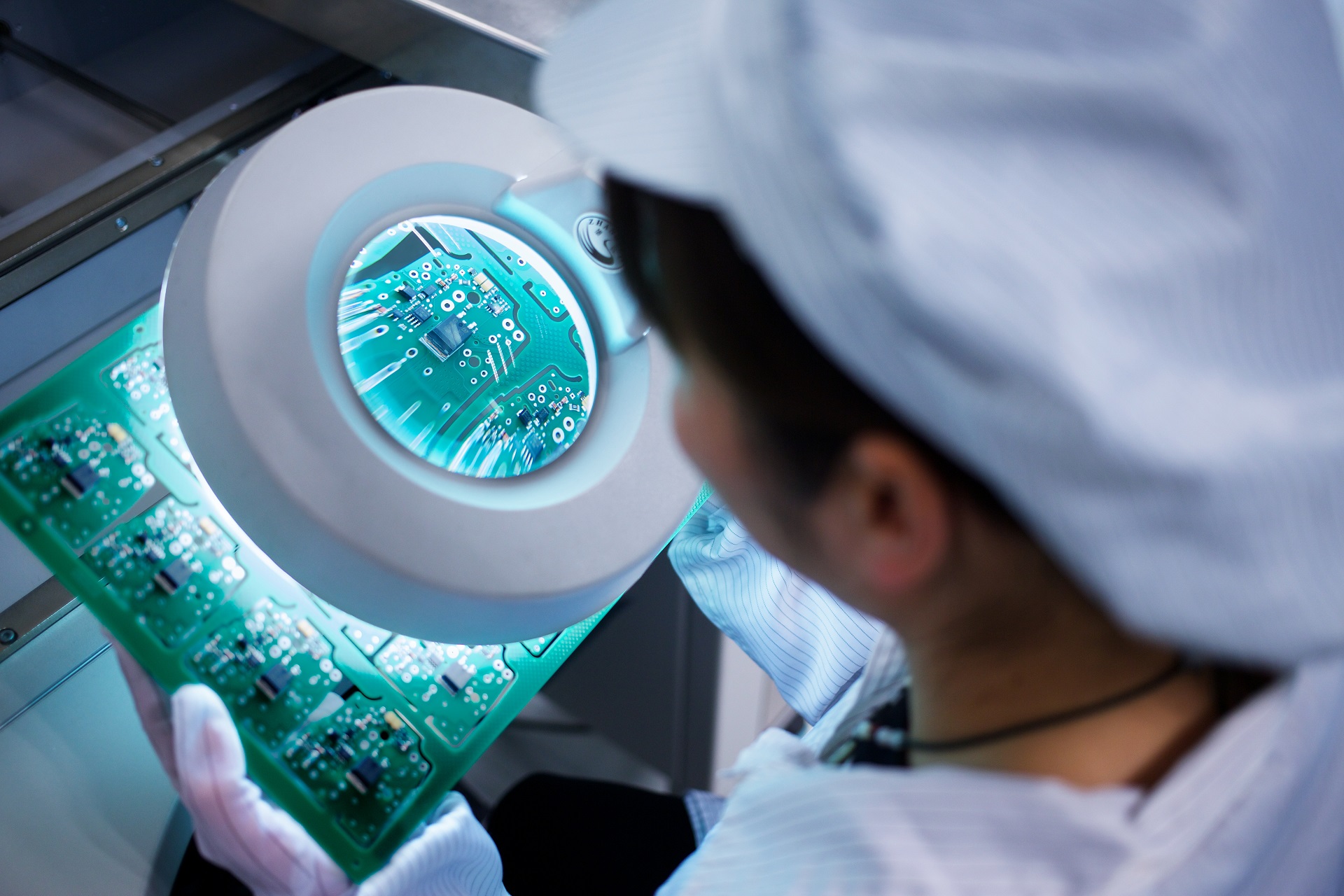

The manufacturing industry has its own nuances. Just like any other industry, the manufacturing sector also depends on many aspects.

From delivering value to driving growth and easing the manufacturing processes, organizations in Industry 4.0 focus massively on operations, supply chain, and distribution cycles.

This ongoing phase of the 4th Industrial Revolution delivers value by embedding the techniques of the operation with digital technologies to create connected enterprises using the data to drive smart actions in the physical world.

The term smart itself encompasses several intelligent forms, which vary from the significance of corroborating digital tools and technologies to driving new innovations in digital infrastructure.

Combining the digital, physical, and virtual worlds creates unparalleled opportunities for growth and productivity for manufacturing services while reframing the competitive landscape with smart products and new service models.

The entire production line and systems make the manufacturing cycle 35% faster and 30% more efficient through Industry 4.0 capabilities.

A recently conducted research asserts the concept of mass customization by delivering the ability to create customized products at high speed and on a scale never possible earlier.

In manufacturing, supply chain elements, contracts management, distribution, and retail deliver resilience, growth, and value addition across the entire value chain of manufacturing processes.

In the last few years, emerging technologies such as IoT, AI, Blockchain, and RPA have become one of the most preferred modes of driving digital value to manufacturing.

Another research suggests that the market value of smart manufacturing will reach USD 550 Billion by 2028.

The products which were not feasible earlier, the processes which looked cumbersome, and the manufacturing tasks which seemed unattainable earlier have become easy with the implementation of digital into manufacturing.

The below discussed key elements strategize the manufacturing cycle, enabling organizations to maximize value from minimum efforts.

1. Digital Connectivity

Almost every industry is maximizing its value with the use of digital, then how come the manufacturing sectors remain unattended.

With the rise in the digital volume of operations, the opportunities to improve process productivity, quality, and efficiency to manage the risks better through integrating emerging technologies such as automation, IoT solutions, AI, cloud, and advanced analytics have become imperative.

2. Digital Engineering

Digitalization forms the core of business processes and operations.

Once the foundation of digital technologies is set, the next step comes is the execution part.

The desired values are not achieved without a digital execution of the technologies, hence, the emerging technologies enhance product design and supply chains, develop smart products, and cultivate upstream and downstream connected ecosystems to deliver value from manufacturing to the masses.

3. Digital Operations

Organizations dealing with manufacturing processes increasingly focus on small-lot manufacturing with immediate potential.

Organizations driven by high end-to-end integrated product data, digital enablement, and data-driven overall equipment effectiveness (OEE) fare well compared to those lacking the digital infrastructure.

The software also plays a vital role in digitizing the entire manufacturing ecosystem of several digital tools and emerging technologies.

Several software ranges from streamlining the manufacturing processes to promoting hassle-free project management to make manufacturing less of a thing digital but more delivering digital, both in terms of quality and quantity.

“Fox ERP for Manufacturing” is an ERP software that revolutionizes manufacturing business processes by delivering value within a few clicks.

It simplifies the production cycle, helps track material consumption, exhibits capacity planning, and handles subcontracting.

The volume of manufacturing processes gets digitized without compromising the value delivery from the business operations across the manufacturing value chain.

Not only it allows businesses to create and manage a Multi-level Bill of materials and Operations as the basic blueprint of the manufacturing system, but it also creates a manufacturing order for production and shows the required quantity to make that amount of item available in the store, avoiding the chances of stockouts.

Conclusion

With the rise in digital transformation, organizations are transitioning from non-digital to digital business processes.

Manufacturing, too, is undertaking the nuances of complex manufacturing processes, providing businesses with automated processes, saving them with extra incurred costs, and enhancing overall productivity.

“Fox ERP for Manufacturing, with its unique features, makes manufacturing processes thrive in its business processes.

Recent Posts

FoxERP

Unleashing the Power of ERP Cloud Migration: Benefits, Challenges, and Options

In the contemporary business landscape, Enterprise Resource Planning (ERP) systems play a pivotal role in driving operational efficiency and facilitating strategic decision-making. With the rapid evolution of cloud technology, organizations are increasingly exploring the option of migrating their ERP systems to the cloud to unlock a plethora of benefits and drive digital transformation.

FoxERP

The ERP Revolution: Navigating Enterprise ERP System Challenges

Enterprise Resource Planning solutions can be a lifesaver for businesses. It enables you to automate all your day-to-day business processes in a centralized and streamlined platform. Today, most business organizations implement ERP solutions like FOX ERP to improve business operations, boost data security and data quality, automate workflows, and enhance customer service.

FoxERP

Unlocking Organizational Success by Embracing the Strategic Roadmap to ERP Implementation

Do you know? The global ERP software market is expected to reach a staggering $78.40 bn by 2026, growing at a CAGR of 10.2%. The global ERP software market is estimated to take over 40% of the market share by 2025.